Several years ago, I endured a problem with my SteppIR 2 element (with 40) antenna. I would calibrate the antenna, and it worked fine from 20-6, presenting low SWR – but if I tuned to 30 or 40, the antenna produced high SWR. If I returned to the previously working 20-6, the SWR was now high as well, and remained that way until the antenna was re-calibrated.

Clearly, there was a calibration corrupting issue when the tape entered the sweep, and after giving the matter considerable thought, I concluded that the clamp assembly had – over time – deformed the fiberglass tubing.

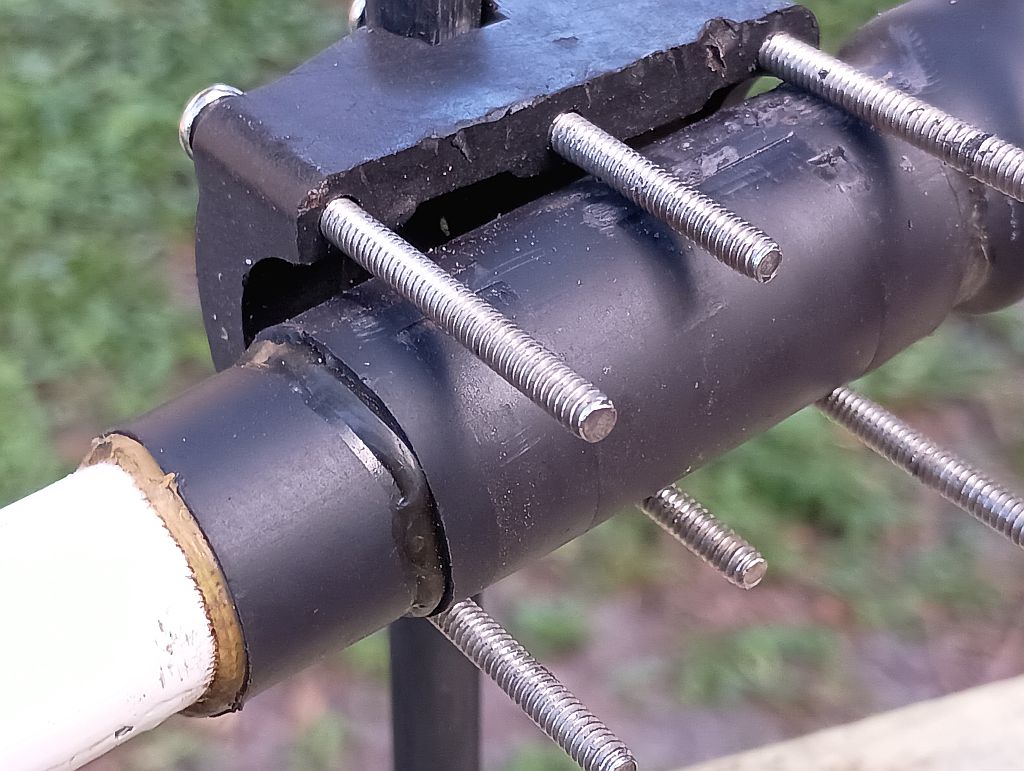

Each clamp assembly has 6 tightly torqued screws that cause the sweep tubing to grip the end of the fiberglass tubing. Initially, the tubing withstands the massive pressure exerted by the 6 screws, but over time (usually several years) – the tubing gives way, and deforms. This creates a partial obstruction that resists the passage of the tape, eventually resulting in “skipped steps” that compromises the calibration.

The solution seems obvious: Get rid of the clamping force, and the tubing does not deform – so the tape can pass freely.

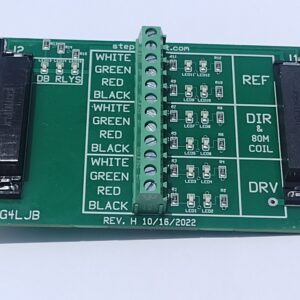

Bill K9HZ came up with a solution that makes great use of 1-1/2″adhesive lined Heat Shrink Tubing (hereafter referred to as “HST“) to keep the sweep and the fiberglass tubing connected. The major downside is: The clamp assembly is reinstalled in it’s original location. This is problematic because the outer diameter of the heat shrink tubing covered sweep tube is now LARGER, and the inside of each clamp requires grinding in order to get it to fit.

Properly prepared, the HST provides an effective and reliable attachment, so the clamp is no longer required to keep them joined. The clamp is still necessary however, in order to mount the spreader bar.

Mounting the clamp OFF of the sweep tubing is the best option – but now the problem is: The inner diameter of the clamp is far too large to grip the fiberglass tubing – even though it’s outer diameter has increased with the installation of the HST.

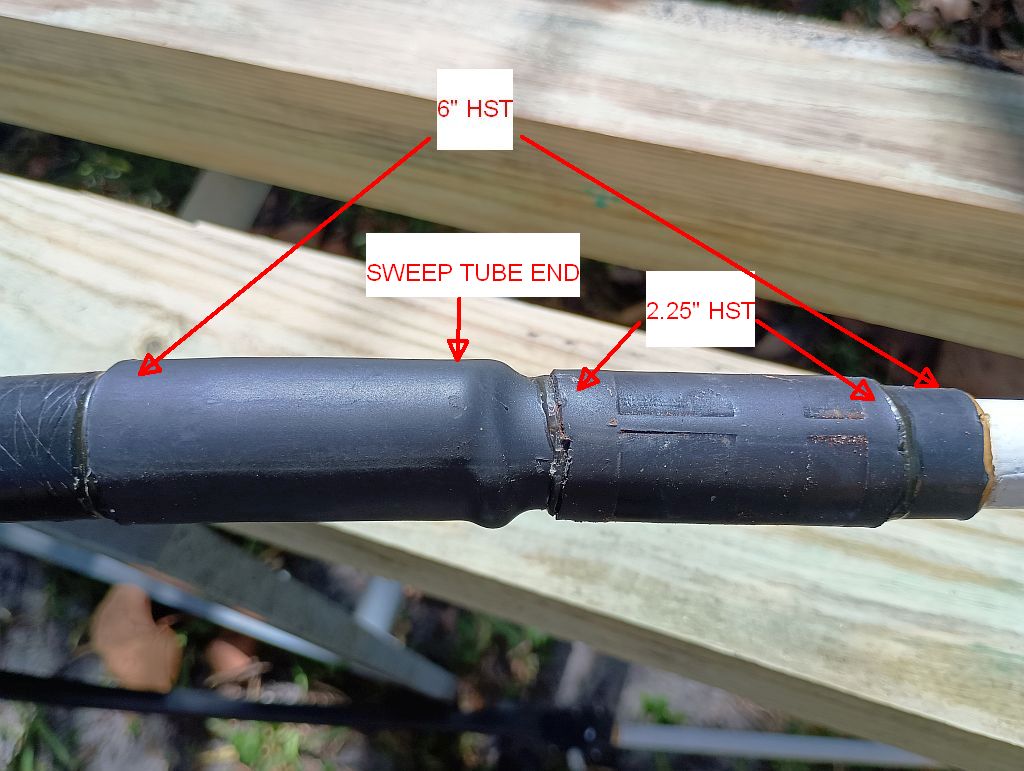

The simple solution: Add a 2nd layer of HST – applied on TOP of the first! This further increases the outer diameter enough for the clamp to get a grip, and mechanically attach the spreader bar.

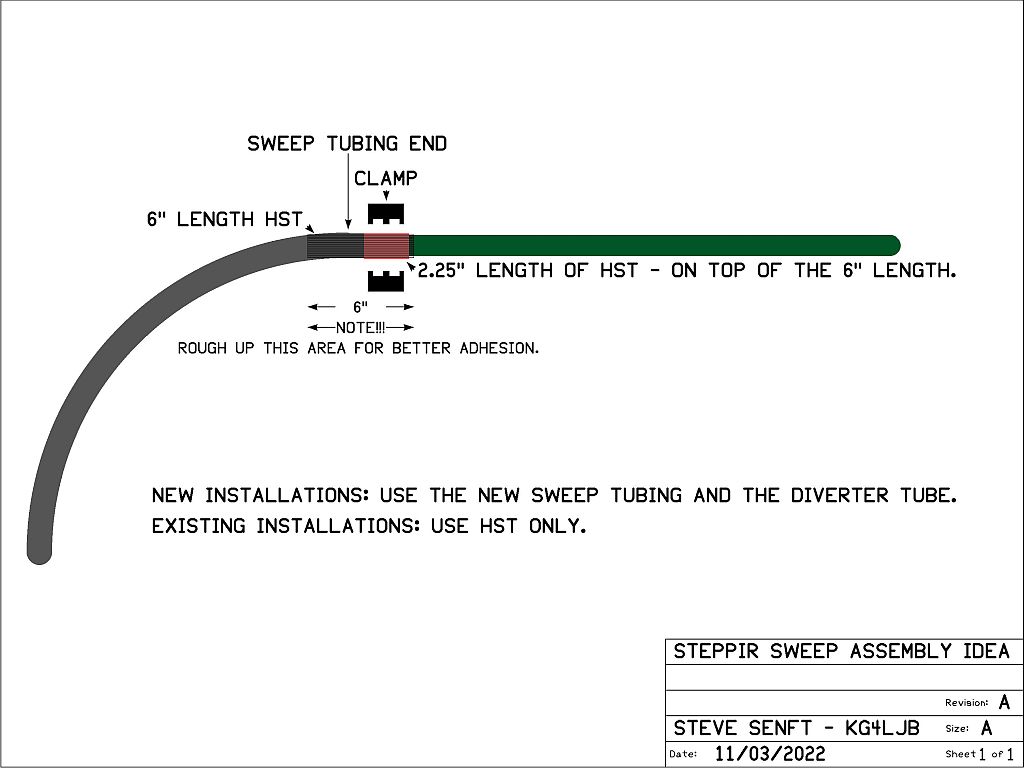

Note the following diagram:

It’s a snug fit.

Installation steps:

- Dismantle the clamps.

- With the sweep and fiberglass tubing still engaged, mark a point on the fiberglass tubing 3 inches from the end of the sweep tubing.

- Use 60 grit sandpaper and rough up the fiberglass tubing out to the 3 inch mark. BE THOROUGH! Rough up the last 3 inches of the sweep tubing. Clean the surfaces with alcohol. Note!!! It’s VITALLY important that the surface is extremely rough, and clean.

- Separate the fiberglass tubing and the sweep. Slide on a 2.25 inch (length is not critical) length of HST – onto the fiberglass tubing FIRST, THEN slide on a 6 inch length.

- Rejoin the fiberglass tubing and the sweep. Slide the 6″ length of HST over the sweep, and position so the center of the HST is centered over the end of the sweep tubing. The tubing should cover all sanded areas.

- Using a heat gun, shrink down the HST. It’s vitally important that THE HEAT GUN IS KEPT IN CONSTANT MOTION – ESPECIALLY when it’s over the sweep. If you dwell too long, you will melt and ruin the sweep tubing!

- Be sure to thoroughly heat all sides of the tubing, and liquify the adhesive.

- This step is IMPARATIVE! Go away for 20 minutes. It is CRITICAL that the HST is allowed to cool down and set up – UNDISTURBED. Premature movement could compromise the bond.

- Slide the 2.25″ length of HST over the end of the 6″ length, then position it’s end at (but not over) the end of the sweep tubing. Shrink it down reasonably well – no need to be super thorough.

- Reinstall the clamps over the 2.25″ HST, then tighten the screws so the clamp grips the dual layer of HST a reasonable amount. Mine had a 3/16″ gap between the clamp halves.

- Done!

This method has been implemented by several hams, and has not only proven reliable, their tuning headaches disappeared.

The only potential down side: You’ll need to slice then heat then peel off the HST if you ever need to dismantle the sweep, and it will doubtlessly leave adhesive residue.